From Kitchen Counter to Craft Chocolate Maker: 5 Stone Grinder Stories That'll Inspire Your First Batch

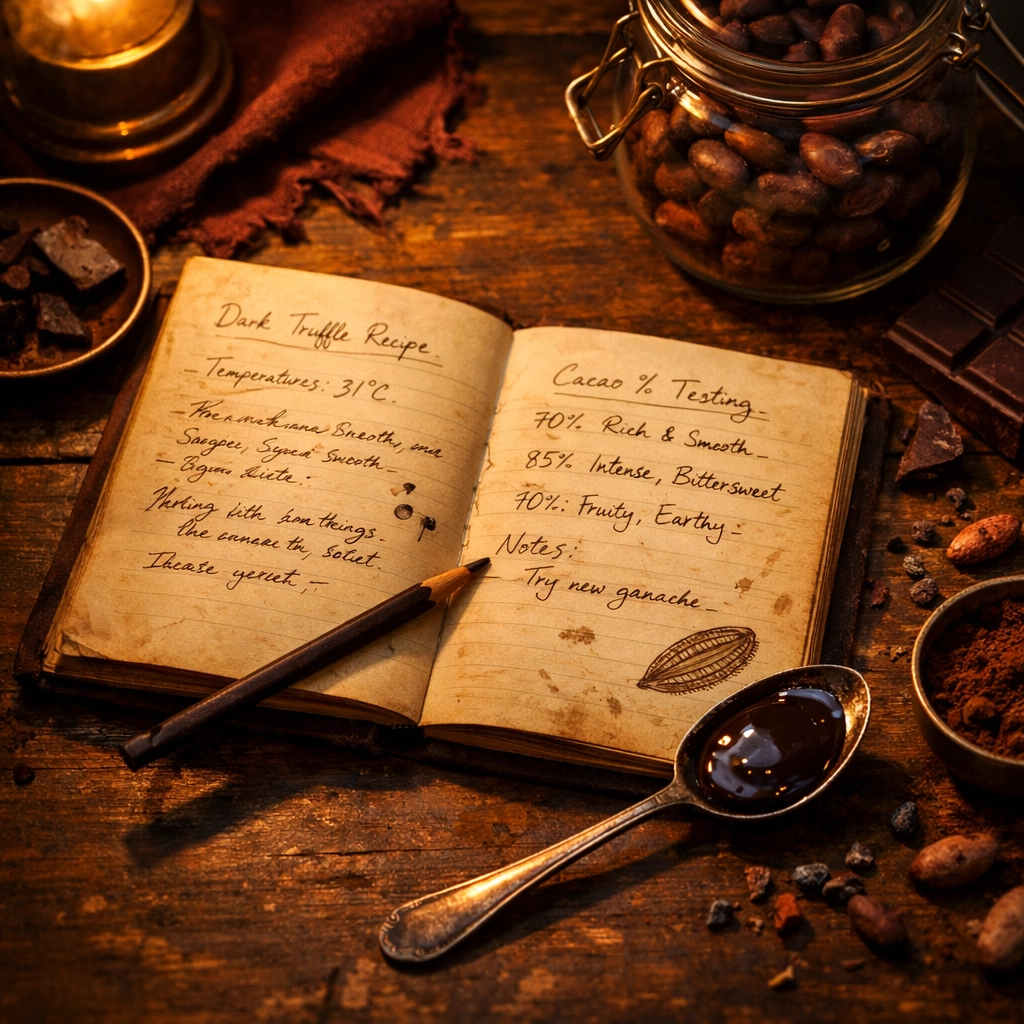

Ever wonder what separates dreamers from doers in the craft chocolate world? It's usually one decision: investing in that first stone grinder and letting it run for 24 hours straight while your kitchen hums with possibility.

Today's Maker Spotlight celebrates five chocolate makers who took the leap from kitchen counter experiments to creating batches that made people stop mid-bite and ask, "Wait, you MADE this?" Their stories aren't about fancy equipment or culinary degrees. They're about curiosity, persistence, and the magical transformation that happens when cocoa nibs meet granite stones.

Story #1: The Weekend Warrior Who Couldn't Stop

Maya, Portland, Oregon

Maya started like most of us do: nibbling expensive chocolate bars and thinking, "I could probably figure this out." She ordered cacao beans online, roasted them in her oven (burning the first three batches), and hand-ground nibs with a mortar and pestle for approximately 47 minutes before her forearms gave out.

"My 'chocolate' looked like sandy paste," she laughs. "It tasted... earthy. And not in a good way."

The breakthrough came when she invested in a compact stone grinder. She loaded it with her roasted nibs on a Friday night, expecting to check on it periodically. By Saturday morning, the transformation had already begun: the gritty paste from midnight had become noticeably smoother, with cocoa butter naturally releasing from the friction and heat.

By Sunday evening, after 36 hours of continuous grinding, Maya tasted something that actually resembled professional chocolate. The particles had reduced to under 20 microns, creating that signature silky mouthfeel. More importantly, the extended grinding time allowed bitter acidic compounds to oxidize and dissipate, leaving behind the complex fruity notes she'd been chasing.

"That first batch changed everything," Maya says. "I understood why chocolate makers talk about their grinders with such reverence."

Story #2: The Career Changer's Midnight Epiphany

James, Austin, Texas

After fifteen years in software development, James was burnt out on debugging code. He wanted to create something tangible, something that brought joy without requiring a software update.

His entry into chocolate making was methodical: he researched everything. Bean origins. Roasting curves. Conching times. But reading about stone grinding versus actually running one for days straight? Completely different experiences.

"The first time I checked my grinder at 2 AM on day two, I had this moment," James recalls. "The chocolate was actively developing flavor while I slept. It felt like collaborative creation: me and this ancient grinding process working together."

James now runs micro-batches focusing on single-origin beans, developing unique roasting profiles for each variety. His technical background helps him track variables obsessively, but he credits the stone grinder's patient, relentless work for the quality that built his reputation.

His advice for aspiring makers? "Don't rush the grind. I tried cutting it to 18 hours once. The chocolate was technically smooth, but it lacked that depth. Those extra hours matter."

Story #3: The Family Recipe Reinvented

Sofia, Scottsdale, Arizona

Sofia grew up watching her grandmother make Mexican hot chocolate, grinding cacao with cinnamon on a traditional metate stone. When she decided to honor that heritage with her own bean-to-bar operation, she knew she needed equipment that respected the traditional stone-grinding method while scaling up production.

Her "ridiculously small chocolate factory" (her words) focuses on maintaining that artisan touch her grandmother valued. Each batch grinds for 24-36 hours, developing the silky texture that made her grandmother's chocolate legendary.

"People ask why I don't speed things up," Sofia explains. "But rushing the process would mean losing the soul of what made my abuela's chocolate special. The stone grinder lets me honor tradition while creating something commercially viable."

She's particularly passionate about roasting profiles: spending weeks developing the perfect roast for each cacao origin before ever loading the grinder. "The grinder can only work with what you give it," she notes. "Garbage in, garbage out."

Story #4: The Accidental Chocolate Maker

David, Burlington, Vermont

David bought a stone grinder thinking he'd make nut butters. Almond butter. Cashew butter. Maybe some tahini if he felt adventurous.

Then a friend gifted him five pounds of cacao beans as a joke.

"I thought, why not? I'll throw them in and see what happens." What happened was a 72-hour obsession where David barely left his kitchen, checking the grinding chocolate every few hours, tasting it, adjusting, learning.

"On day one, it was obviously terrible: gritty, acidic, harsh. Day two, things started smoothing out but still tasted raw. By day three, I had actual chocolate. Not perfect, but actual chocolate I made myself."

That experimental batch launched a side business that eventually became his full-time passion. David now processes batches that can handle larger quantities, typically grinding for three to four days to achieve his signature ultra-smooth texture and complex flavor profile.

His approach embraces the science: "Day one is oxidation: those harsh acidic compounds off-gassing. Day two focuses on particle reduction, getting everything silky. Days three and four? That's where magic happens, where flavors refine and deepen."

Story #5: The Teacher's Summer Project

Rachel, Asheville, North Carolina

As a middle school science teacher, Rachel wanted a summer project that combined chemistry, patience, and something delicious. Stone-grinding chocolate hit all three criteria.

She documented everything like a lab experiment: temperatures, grinding times, bean varieties, flavor development over days. Her students' parents became her first customers after she brought samples to back-to-school night.

"The stone grinder became my classroom assistant," Rachel jokes. "Nothing teaches patience and process like watching chocolate develop over 48 hours. I use it as an example for my students now: good things take time, precise conditions matter, and chemistry is delicious."

Rachel's systematic approach helped her identify the sweet spot for her preferred style: 40-44 hours of grinding for beans with higher acidity, 30-36 hours for mellower origins. She tracks every variable in a spreadsheet that would make any data scientist proud.

The Common Thread

What connects these five makers? None of them rushed the process. They each discovered that stone grinding isn't just about reducing particle size: it's about transformation over time.

The grinder becomes a partner in creation. You provide quality beans, proper roasting, and patience. The grinding stones provide consistent friction, gentle heat, and relentless refinement. Together, you create chocolate that tastes like it was made with intention.

Want to start your own chocolate-making journey? Join the Cocoa Craft community where makers share techniques, troubleshoot challenges, and celebrate those first perfect batches. Our Formulation Tool helps you plan recipes, track ingredients, and calculate ratios: all the technical support these makers wish they'd had when starting out.

Already grinding? Log in to access our Chocolate Lab resources, connect with fellow makers, and explore equipment that'll take your craft to the next level.

Because the best chocolate story is the one you're about to write: starting with your very first batch.

By Cocoa Craft – Helping makers transform beans into extraordinary chocolate, one grinding session at a time.

Ready to share YOUR maker story? Join our community and let us know what inspired your chocolate journey. We feature maker spotlights every Monday, and your story might be next!